Career Preparation in the Classroom

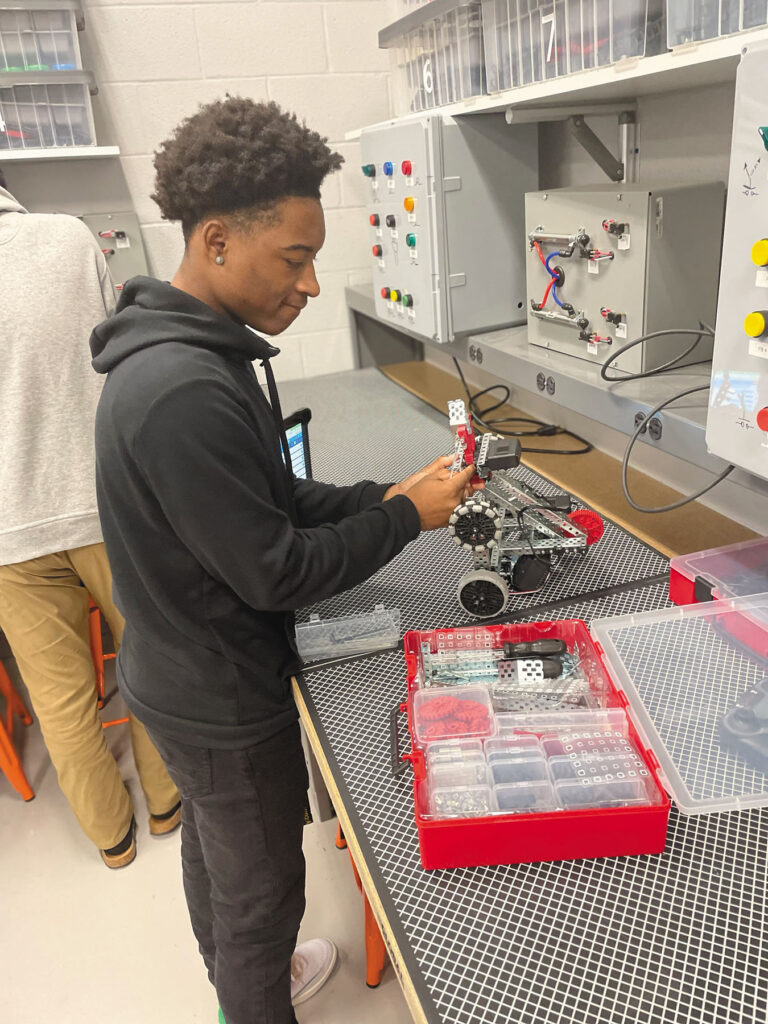

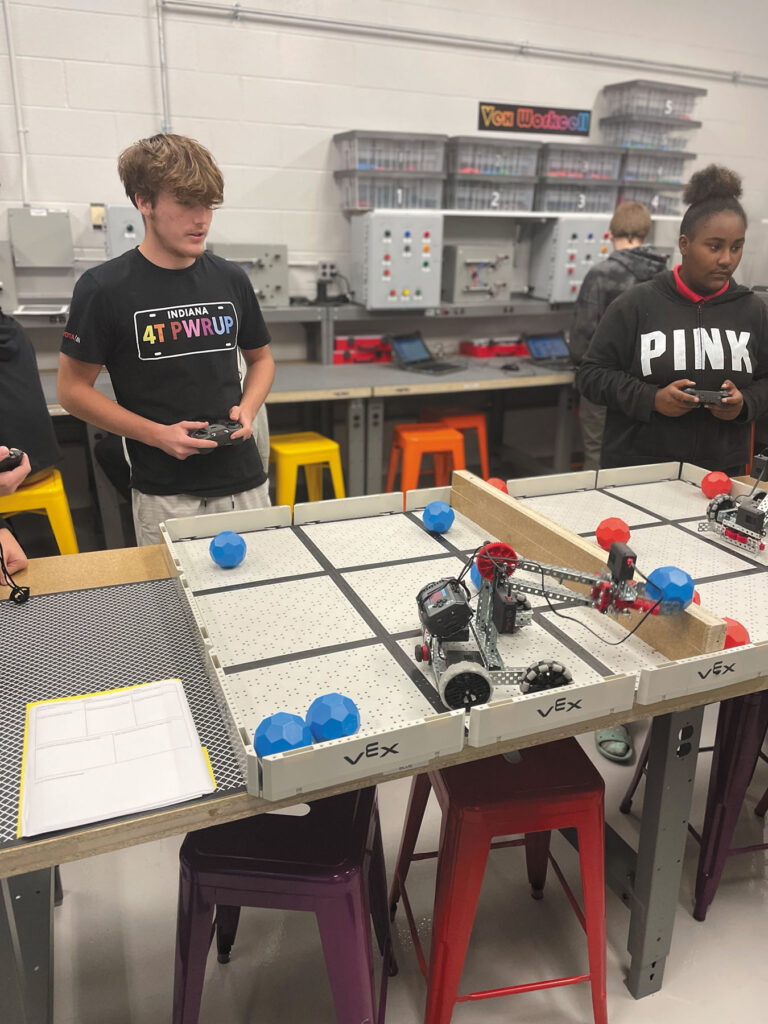

In Gabriel Golba’s manufacturing classes at Bosse High School in Evansville, IN, students explore robotics, hydraulics, industrial design, and reading blueprints. It’s not so different from many career and technical education programs around the country.

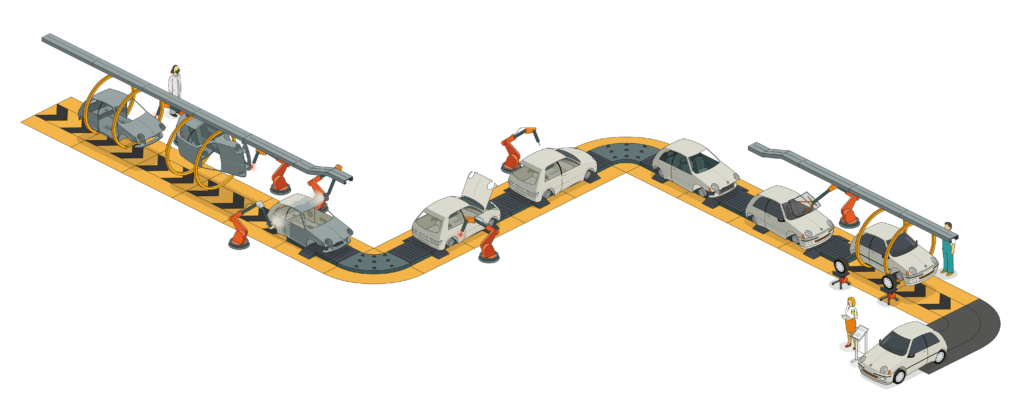

But for Golba’s students, that classroom study is just the beginning. For one thing, an old engine repair workspace in the school has been transformed into a state-of-the-art moving assembly line, courtesy of Toyota Motor Manufacturing, Indiana, which introduces them to actual manufacturing. By the time the students are in the second semester of their senior year, they are spending four days a week working on full-size assembly lines at the nearby Toyota Indiana plant, earning an hourly wage and working half days alongside Toyota employees.

It’s all part of the school’s 4T Academy, a partnership with Toyota that’s now in its second year at Bosse and has expanded to two other Toyota manufacturing sites—Toyota West Virginia and Toyota Mississippi. It’s also one of the proudest achievements of NASSP President Aaron Huff’s time as principal of the school.

“We look at the program as a way to prepare students for the future,” Huff says. “The point isn’t necessarily to steer them toward the Toyota workforce or entry-level employment at the plant. It was designed around helping students take what they learn and transition into any industry or into higher education. We want to make sure we’re preparing students to be successful.”

A Popular Program

Golba was the perfect instructor for the two-year program, having taught a wide range of tech-ed programs in his more than 20 years in the classroom. “I think the kids love it,” he says. “This is an elective course, which means that if they don’t like it, they can just drop it. But we retained 90% of our students after their junior year.”

Senior Jaden Cooper likes that Golba has the students for an extended three-period block of instruction. “It’s more reasonable to focus on your classes with all the time on your hands,” he says. “The curriculum is very understandable, and I’ve also been able to use some of the skills I’ve learned and applied them in my life outside of school.”

If you ask students what they want to do after high school, many of them still don’t know, and the program can help them figure that out, Golba adds. As it turns out, of the 15 students who graduated last year, four are currently working at the plant, and one is in college studying engineering but participates in a summer intern program at Toyota.

By the time the students are in the second semester of their senior year, they are spending four days a week working on full-size assembly lines at the nearby Toyota Indiana plant, earning an hourly wage, and working half days alongside Toyota employees.

Chad Goldsmith of Toyota, who has worked with 4T programs at Bosse and other locations, says that aim of helping students figure out a plan for the future is intentional—and gratifying. As they go through the program, “students begin to ask more questions about manufacturing careers and envision themselves in roles at the plant. This shift represents one of the most significant positive impacts our program offers. It allows students who previously had no concrete plans to now see a potential path forward and a fulfilling career in manufacturing.”

In fact, many of the current seniors intend to continue with Toyota in some way after graduation. Marciana Jennop hopes to work at the plant while attending the University of Southern Indiana. “Toyota helped me with my decision because it gave me pieces of information on how I can work there while going to school. Before I joined the program, I had no clue of what I wanted to do after high school.”

Jesus Avila wants to take a job at Toyota and see where it leads. “I could either save up for school, or try going into a management position, or even go to a different plant as a manager,” he says.

A Teaching Partnership

Golba and Toyota instructor Chandra Ingler are the core of the program’s teaching staff, and they work closely to coordinate the curriculum and the on-site learning at Toyota. Golba admits that his beard is whiter from the late nights he’s spent mastering new content that he teaches. “You have to stay smarter than the students,” he says. “If I’m teaching robotics and a kid has a question, I’m trying to make sure I stay ahead of them. You know they are going to challenge you and make you learn more.”

Last year, the program’s initial year, Golba and Ingler sat in on each other’s classes to improve their collaboration. In a broad sense, Golba teaches the academic content and Ingler focuses more on Toyota values and production processes as well as some “softer skills” such as interviewing, teamwork, time management, and financial planning.

“I’m so glad I’ve gotten this opportunity to work with the students at Bosse,” Ingler says. “They are very receptive and eager and excited, and they have a lot of energy. I hope the students can get some of the same satisfaction that I’ve gotten from my career at Toyota. I want them to see they have the chance to decide if it’s something they want to pursue.”

Huff is pleased by the connection the students have made with some of their older Toyota coworkers. At graduation last year, he watched some of the seniors interacting with the workers and with some retirees who volunteer at the school to help with the program. “Some of the workers came on their lunch break to watch these kids graduate,” he says. “It was really neat to see that level of camaraderie and that commitment to take these young people under their wing and prepare them for the future.”

Making Education Relevant

That connection to the outside world really is the heart of the program to Huff. “We need to make education relevant,” he says. “Being able to show the students that what they’re learning applies to what they might be doing down the road is a space we want to be in. And that also helps with student engagement and student attendance.”

The program is capped at 20 juniors and 20 seniors because of space limitations. As a result, and also because the program offers practice for real-world activities, the students must sit for interviews before they can enroll.

During their junior year, much of the work is classroom based, similar to most traditional career-tech programs. Ingler works with the juniors one day a week and two days a week with the seniors first semester. The juniors also take regular field trips to the plant, where they tour the facility, meet with employees, and participate in some on-site activities. By senior year, Golba says, they are digging much deeper into the content as they prepare for their final semester. By then, students leave during lunch and spend a half day at their internships at the plant.

After the appropriate training, they work through rotations of different parts on the assembly line, such as welding or plastics or body work. In each instance, they work alongside regular Toyota employees. One thing that surprises the students, Ingler says, is how modern the facility is. “People might tend to think of an automobile factory as being dirty and hard, physical work. But when the kids see how clean it is, and that the workers aren’t all rushing around, they get a whole different perspective.”

Despite the limitations on enrollment, Huff hopes Bosse becomes something of a hub for other 4T programs, with satellite locations across the five comprehensive high schools in the area. The school has already hosted visitors from other states who want to learn more.

Current student Alisha Wright is confident the program has prepared her for life beyond high school, especially given the discipline and high expectations required to work in the factory. “We’re constantly trying to better ourselves, to love and respect one another, and learning how to move forward with our work and lives,” she says. “We work through the obstacles with optimism, knowing that we can accomplish any task by putting in more practice and more motivation.”

Dan Gursky is a freelance education writer and editor based in Washington, D.C.